When joints are subject to fatigue loads with direction reversal, slip-critical joints are necessary. They include connections in presses, crane supports, and bridges. Some connections are subject to many loading cycles that may lead to fatigue. Such slippage eventually leads to elongated holes and even greater slippage. When significant load reversal occurs, pretensioned joints may be required to eliminate cyclic slippage. Bending members that are subject to complete load reversal is another example. Some applications involve load reversal, such as when rotating members experience alternating tensile and compression loading. Once the slippage has happened, it won't recur because all subsequent loading would be of the same nature.

The first time it's loaded, minor slippage may occur. For example, consider a hopper that is designed to contain some granular material. Snug-tight joints can be acceptable for many applications, because minor slippage may not affect the connection performance negatively. No slippage is expected in this joint, but the possibility exists.

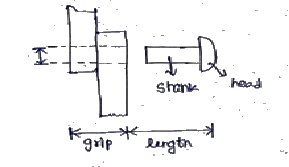

The second possibility is that friction, introduced by the clamping forces from the pretensioned fastener, may resist the shear loading. The bolts or rivets may bear against the sides of the holes, causing the bolt or rivet to shear at the same time. When a mechanically fastened joint is loaded in shear-when one member tends to slide over the other because of the applied forces-one of two situations can occur. Riveted joints behave more like snug-tightened joints, but the pins in this case are the rivets, which typically are about half the strength of A325 bolts. This is similar to a binder clip that holds together a stack of papers, not because holes are punched in the paper, but because the binder clip presses the sheets of paper together, and friction keeps the packet together.ĪSTM A325 bolts have a minimum tensile strength of 150 to 120 kilopounds per square inch (KSI), depending on the bolt diameter, while A490 bolts must fall between 150- and 170-KSI tensile strength. Slip-critical joints work by friction: The pretension forces create clamping forces, and the friction between the contact surfaces works together to resist joint slippage. In layman's terms, the bolts act as pins in snug-tightened and pretensioned joints, similar to a brass brad that holds together a stack of hole-punched papers. Each part of the overall connection behaves independently. The amount of compression on the protrusions indicates what level of tension has been applied to the bolt.įigure 1: In this illustration, the connection has two separate components: a welded connection on the left and a bolted connection on the right. Direct-tension indicators are special washers with protrusions. When the required torque is achieved, the stud twists off.Ĥ. Twist-off-type tension-control bolts have small studs on the end of the bolt, opposite the head. The calibrated wrench method measures torque, which is correlated to the tension applied to the bolt.ģ. The turn-of-nut method involves snugging down the bolt and then turning the nut an additional amount, which is a function of the bolt diameter and length.Ģ. Under Section 8.2, four methods of making these joints are acceptable:ġ. In a pretensioned joint, bolts are installed so they are under significant tensile load, with the plates under compressive load. Background on Bolted Connectionsīolted joints are described in the American Institute of Steel Construction's (AISC's) Specification for Structural Joints Using ASTM A325 or A490 Bolts as snug-tightened, pretensioned, or slip-critical.Ī snug-tightened joint is tightened by the force of an impact wrench or by an ironworker using an ordinary spud wrench to bring plies into firm contact. Such an assumption can lead to disastrous consequences. However, determining the connection's total load capacity isn't as simple as adding together the sum of the individual components-the welds, bolts, and rivets.

RIVET BOLT CONNECTIONS FULL

For new construction, bolts and welds may be required to work together in connections in which the materials being joined first are secured with bolts and then are welded to obtain full connection strength. Such situations may occur during retrofit, repair, or strengthening projects. Today mechanical fasteners typically are bolts, but older structures may include rivets. In a variety of structural situations, an engineer may need to assess the strength of a connection made with welds and mechanical fasteners.

0 kommentar(er)

0 kommentar(er)